Last August, I announced that Faerie’s Dance would start manufacturing their own line of organic cotton panties. By October, we’d put a down payment on our fabric and had our first patterns. At the time, I posted that we’d launch those first few designs in late January or February.

It’s April, and many of you (including myself) are wondering, where the heck are these panties?! Good question. Let’s recap.

When we left the deposit on the fabric, the manufacturer (a small, family-run, GOTS certified manufacturer in India) told me it would be about 60 days to completion. So I lined up our Stayton, Oregon based seamstress for end of December and our Portland based printer for early January. And for about 2 or 3 weeks, we were on schedule.

Once we were ready to get our low-impact dyed colors done, I learned I needed the Pantone color numbers to proceed. I’d already picked the colors to match the latex-free elastic trims. Unfortunately, the elastic seller wasn’t able to tell me what the Pantone numbers were. And it turns out, buying what I thought would be a swatch card is actually a reference encyclopedia running about $900. After a bit of a confusion and scramble, I mailed pieces of elastic to India and they were able to match the colors that way.

This small glitch put us 2 weeks behind.

Being a small business owner, I’m aware that things can occasionally (read: regularly) go wrong. So when a machinery part broke down at the fabric manufacturer and they told us (very apologetically) that there would be another two week delay, there really wasn’t much I could do. (Other than lament that the Hearts A’flutter panties wouldn’t be ready in time for Valentine’s Day.)

At this point, we were 4 weeks behind.

Now, we do a lot of importing. Our best-selling bra line is from Italy. When you ship small, lightweight items, they generally need to go by air because there’s not enough weight and/or volume to justify hiring all or part of a sea shipping container. So I really (really!) should have known better. But in my excitement of getting our first custom made fabric, I did not account for the time delay of shipping sea versus air. Air usually takes a week, two tops. Well for 1300 lbs of fabric, you really can’t ship by air. (Unless you want to pay a ridiculous amount of money and waste a lot of jet fuel, neither of which are high on my priority list.) So my allotted “shipping week” was taken over with special forms required for sea shipments. Then the actual shipping time took an additional 4 weeks.

Suddenly, we were 2 months behind.

Ok, but February 27th is the big day – fabric is arriving!! I figured a few days for customs clearance, and I would be able to get the fabric to the seamstress first week in March. I make calls. I schedule. The fabric arrives! And I am the lucky winner of a special Vehicle and Cargo Inspection System (VACIS) exam. If you just clicked that link, yes, the winner of a VACIS exam also wins the right to pay extra for the exam – even if the cargo is deemed legal and no contraband is found. To make a way-too-long-story short, customs finally released my fabric on the afternoon of April 4th. They held it more than 5 weeks. My business was required to pay nearly $400 in additional exam fees, and no contraband was found.

Et voilà, we were now 3 months behind.

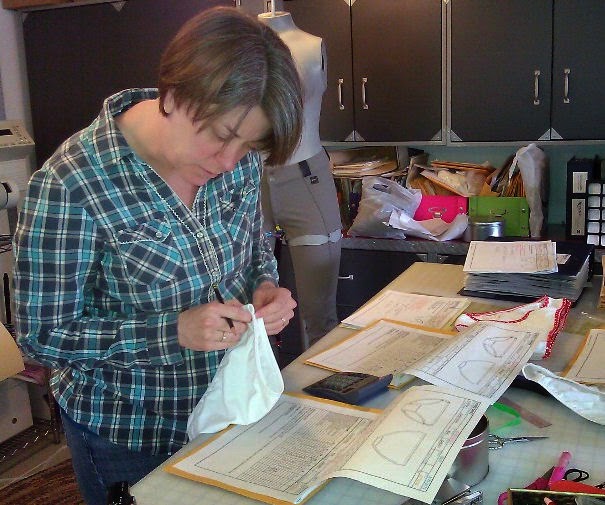

So I call the seamstress, and guess what? She’s in the middle of someone else’s project. This was not at all unexpected, and I was really grateful that she (a small business owner herself) was still willing to work my project in. I’m sure some of my delays had her scrambling to find other projects. She worked in all of the sample sewing and fittings (which are now done! yay!); and is able to start full production April 28th.

And just like that, we are 4 months behind.

I’d love to offer you all a list of the lessons I’ve learned during this experience, but it’s a blog post, not a novel, and room is limited. And for the sake of all the issues I still haven’t run into and the fact that I haven’t even called the printer back yet, let’s just call it 5 months behind and hope for a July launch. Just in case.

That said, the single biggest, most overwhelming, really smack-in-head, light bulb on, ah-ha lesson that I’ve come away with is… humility.

I am humbled by the efforts of the fabric maker, customs broker, seamstress and patternmaker in support of my project.

I am grateful to the many customers who’ve asked about the panty status, and who’ve not only been understanding about the delays, but even outraged on my behalf over the extra customs costs.

I am overwhelmed by the vast effort that goes into bringing the simplest of items to market.

And most of all, I am embarrassed by all the times I’ve been frustrated with manufacturers over delays they’ve had.

I’m going to go a little easier on folks from now on, including myself. How many of you are harder on yourselves than you need to be?

Combining this with the experience of getting judgmental e-mails, I’m going to make an extra effort to be a bit more empathetic all around.

And just like that, I found a little peace through adversity.