To live sustainably is to do so in such a way that reduces our impact on the environment around us. In the past years, the concept of sustainable living has changed how businesses and brands develop their products and marketing. In the same way, more and more people are drawn to living an eco-friendly life. A recent Bosch survey of 2,000 Americans found that 64% care about the planet’s health as much as they do their finances. As much as 66% claimed they’d be “willing to try anything that can help save the environment,” starting with small habits such as turning off the lights or taking quicker showers.

Of course, sustainable living is great not just for the environment but for our general wellness as well. In this post, we’ll explore the different aspects of our personal wellness and how sustainable living can help improve it.

Physical Wellness

When we live sustainably, we approach life more mindfully and intentionally. This involves choosing our actions carefully, from the clothes we wear to the food we eat. Adopting a vegetarian, vegan, or organic diet is a common first step to sustainable living, reducing individual environmental damage while staying healthy and even boosting weight control.

Modern weight loss programs today reflect this shift towards mindful, sustainable living by focusing on building healthy habits. Instead of following the restrictive rules of dated, fad diets, experts recommend focusing on eating nutritious foods instead of categorizing them into “good” and “bad” foods. This can help change your relationship with food for the better. Adopting an active lifestyle can also help you stay physically healthy without harming the environment while preventing an unhealthy fixation on food.

Mental Wellness

Most people don’t realize that living sustainably will also take effect internally. Insights from Earth.org indicate that environmentally aware people may suffer from climate anxiety — a chronic fear of environmental doom. In today’s digital age, learning about environmental issues, from wildfires to natural disasters, through real-time news (aptly dubbed “doomscrolling”) can be harmful to our mental health.

The good news is that living a sustainable, eco-conscious lifestyle can help alleviate some symptoms of common conditions like depression and anxiety. By visiting and spending time in green spaces, we can improve our health and well-being and feel more relaxed or energized. Our individual sustainability efforts and daily mindful practices can also help us develop a more resilient mindset. This resilience can help us further work on important issues such as ecological protection, renewable energies, and the protection of vulnerable communities.

Financial Wellness

Finally, beyond its impact on our physical and mental health, a sustainable lifestyle can also benefit our financial wellness. One of the misconceptions of healthy and environmentally-friendly living is that you will end up spending more on organic and exclusive products and services. However, we should be wary of companies who indulge in greenwashing to profit from the eco-conscious demographic.

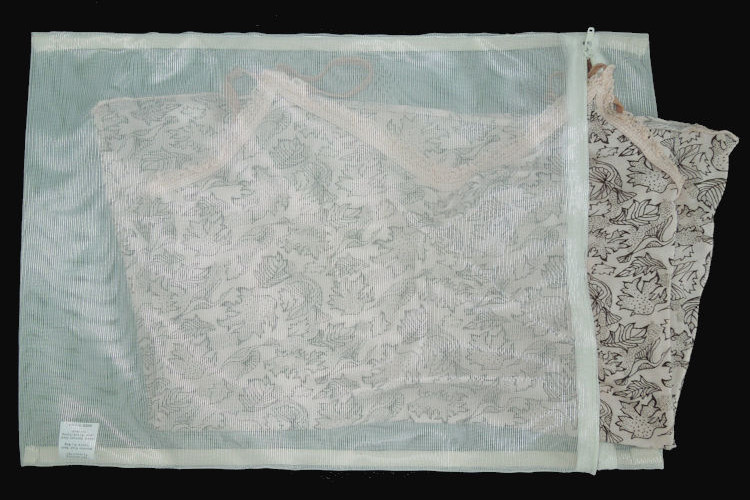

In fact, it’s best not to center your sustainable living on what you consume but on how you consume. In a previous post on maintaining a sustainable wardrobe, we discussed essential tips such as organizing your closet and sourcing your OOTDs from charity shops. Instead of relying on fast fashion and faux “green” clothing labels, one of the best ways to reduce environmental damage is by recycling unwanted items and buying from these sources. You can also borrow or rent clothing and outfits you need if you know you will only use them once.

At the end of the day, pursuing a more sustainable life is as advantageous for you as it can be for the environment. Participating in sustainability initiatives and projects in your community can also help improve your social wellness by exposing you to like-minded people and keeping you motivated and accountable in your sustainability journey.

For more on organic clothing and sustainable living tips, feel free to browse around.